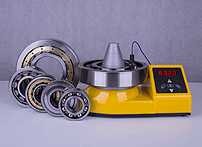

TowerType Bearing Heater 45-120/260 for hot mounting of rolling bearings

TowerType Bearing Heater 45-120/260 for hot mounting of rolling bearings

Most premature bearing failures may be attributed to poor workshop practices when the bearing was fitted.

Misalignment, damage to the surrounding structure (shaft or housing), applying force so that it gets transmitted from one ring through the rolling elements to the ring being fitted, use of the wrong tools, dirty conditions leading to contamination inside the bearing and a multitude of other causes can lead directly to premature bearing failure.

About hot mounting

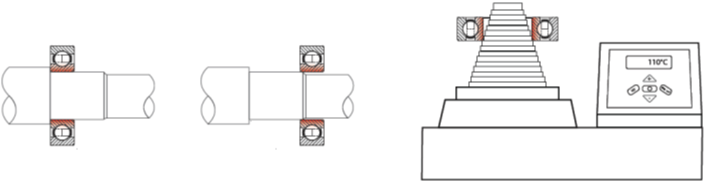

The force needed to mount a bearing increases considerably with the size of bearing. Because of this need for greater force larger bearings (> 50 mm bore diameter) cannot easily be pressed on a shaft or into a housing at room temperature. Therefore the bearing or the housing are usually heated prior to fitment.

The necessary temperature difference between the bearing and seating depends on the magnitude of the interference fit and also the bearing size. Normally a bearing heated to 90°C – 110°C may be mounted on the shaft with ease. Sealed and shielded bearings should be heated up to maximum 90°C, so as not to exceed the drop point of the grease inside the bearing, causing it to liquefy and leak out.

Never heat a bearing above 120°C, avoid localized heating of bearing rings and never heat a bearing using an open flame. Extreme temperatures can cause structural changes in the bearing steel which can permanently alter dimensions or hardness.

About Portable Bearing Heater BH 45-120/260

Application

The ZVELCO Portable Bearing Heater 45-120/260 is designed for uniformly heating ball and roller bearings with an internal diameter ranging from 45mm to 120 mm and weighing up to 15 kg. The bearing is placed onto the tower, which has steps corresponding to the popular bearing internal diameters.

Description

This heater operates at high frequency making it extremely efficient. There are options to heat the bearing or other workpiece for a specific time or to a specific temperature. The integrated predictive temperature control function ensures that the bearing is heated evenly and the selected temperature is achieved precisely and quickly – with no risk of bearing overheating and grease leakage. The heater may be set to maintain the workpiece at the required temperature once it has been attained. In addition to bearings this heater is also ideal for heating other ring shaped metal components such as gears, pulleys, bushings, flanges, pinions, etc.

The heater is very light, it can be carried to where it is needed in the workshop or to site, as long as there is mains power available. It can also be used in tight spaces without difficulty and is extremely easy to operate. Simply insert the plug, connect the temperature probe to the inner ring of the bearing, select the required temperature on the digital display and press the start button.

When mounting hot bearings, clean, lint-free protective gloves should be worn. Before proceeding, the shaft should be exmined to ensure that there are no nicks, burrs or other blemishes; it should be lightly lubricated with thin oil and the bearing should be positioned exactly at right angles to the shaft. Push the bearing along the shaft to its abutment and hold the bearing in position until it cools a little and a tight fit is obtained.

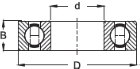

Technical Data:

| Voltage and Power | 230V/50Hz, 10A, 2kW | |

Applicable bearing sizes and weight  | d | 45 – 120mm |

| D | Max 260 mm | |

| B | Max 120 mm | |

| Weight | Max 15 kg | |

Automatic Temperature System

| 20-180°C, in step of 1°C +/- 3°C up to 110°C | |

Automatic Time System

| 0-99 min 59 sec Steps of +/- 0,1 minutes | |

| Dimensions of device | Height H Width W Length L | 250 mm (over tower-280 mm) 200 mm 300 mm |

| Dimensions of carrying case | LxWxH | 350x220x300 mm |

| Weight of device | 6,2 kg | |

Compared with traditional heating methods and various types of induction heaters, the advantages of BH 45-120/260 are as follows:

- Flexibility: Designed to heat a wide range of bearings

Whether you use your bearing heater in the repair shop or out on site you will need to be able to heat various sized bearings for fitment. The TowerType Bearing Heater can accomodate multiple bearing sizes, both Imperial and Metric. - Portability: Light and compact enough to be carried easily and used anywhere

Traditional induction heaters are very heavy and not easily portable so the bearing must be taken to the area of the repair shop where the bearing induction heater is located. This can be inconvenient if you are trying to get several things done at once. The TowerType Bearing Heater is lightweight, portable and can be easily moved from the area of the shop to another or even to a remote site. - Thermostat: Automatic temperature/ time heating control When you are busy multi-tasking in a repair shop, the last thing you have time for is to watch your bearing heat up. The TowerType Bearing Heater offers a convenient thermosat that ensures that the bearing will reach the desired temperature. When this level is reached a buzzer sounds and constant temperature is maintained until you are ready to install the bearing. This feature will help improve productivity.

- Reliability: The simple design of units are warranted for one year

Heating of bearings should be a routine task that does not create difficulties. You need a bearing heater that will do the job day-in and day-out withouth problems or malfunctions. The TowerType Bearing Heater is assembed from quality and simple components. The TowerType Bearing Heater is guaranteed for one year against manufacturing defects. - Affordability: Economical and competitive price

TowerType Bearing Heater is priced economically for maintanance and repair operations. - Ease of Use: No training is necessary

Some bearing heaters require training and practice to heat a bearing to proper temperature. The TowerType Bearing Heater is easy to use and almost anybody can handle it at a repair shop. - Versatility:

Besides bearing and bearing rings, other metallic rings can also be heated - Quietness and cleanliness:

- Contents of delivery:

Induction heater device

Temperature probe

Protective gloves

Instruction for use

Carrying case